| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : AILUSI

Certification : CE,ISO

Place of Origin : JIANGSU

MOQ : 1

Price : 700-4000USD

Payment Terms : D/A, L/C, T/T

Supply Ability : 10

Delivery Time : 35

Voltage : 220V, 220V/50Hz

Type : Filling Machine

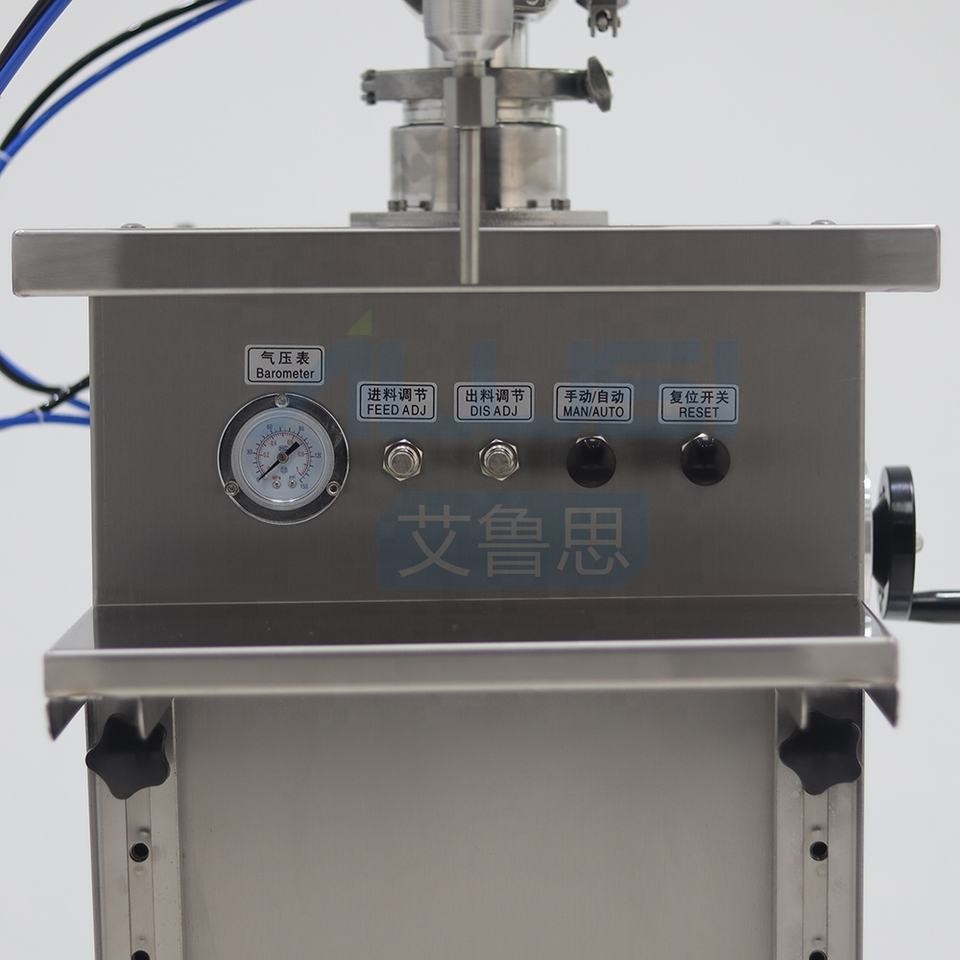

Automatic grade : Semi-Automatic

Condition : New

After-sales service provided : Online support

Filling Material : Beer, Milk, Water, Oil, Juice, Honey/Lotion/Gel

Machinery Capacity : 20000bph

Power : 2KW

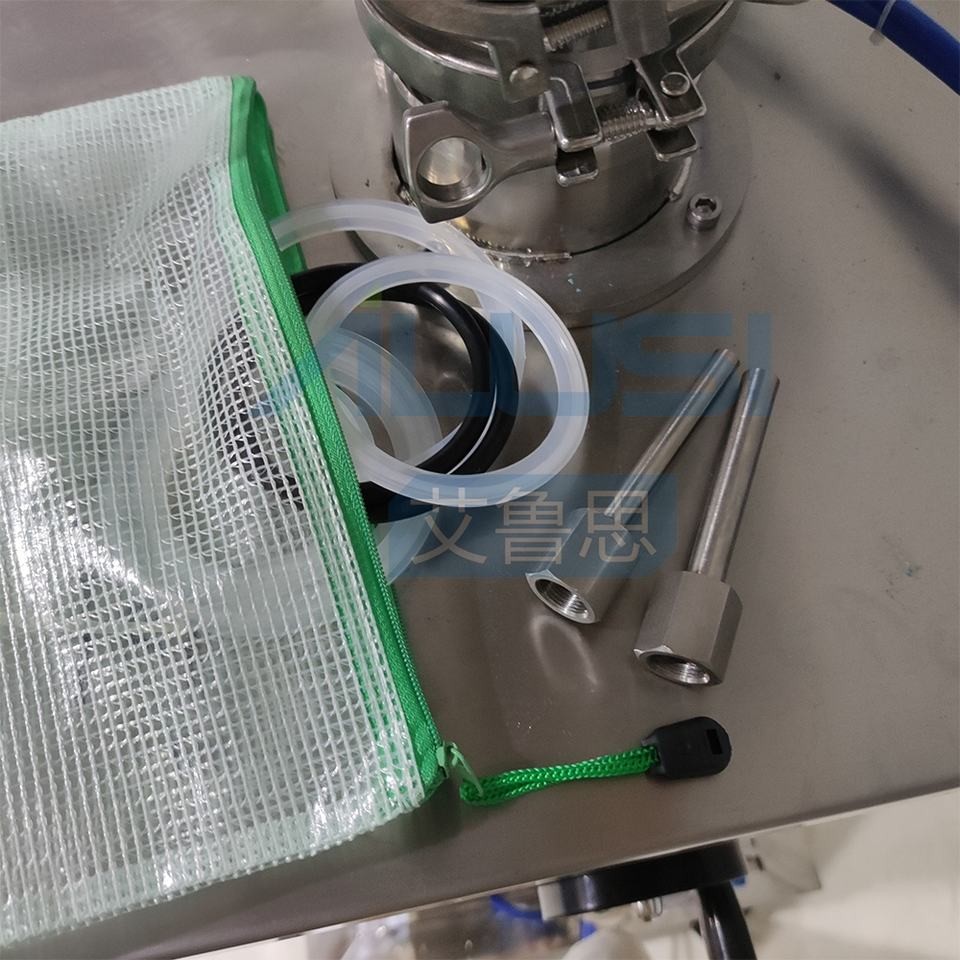

Material : SUS304 and SUS316L

Power of Paddle Mixing : 0.37kw

Weight : 70 Kg

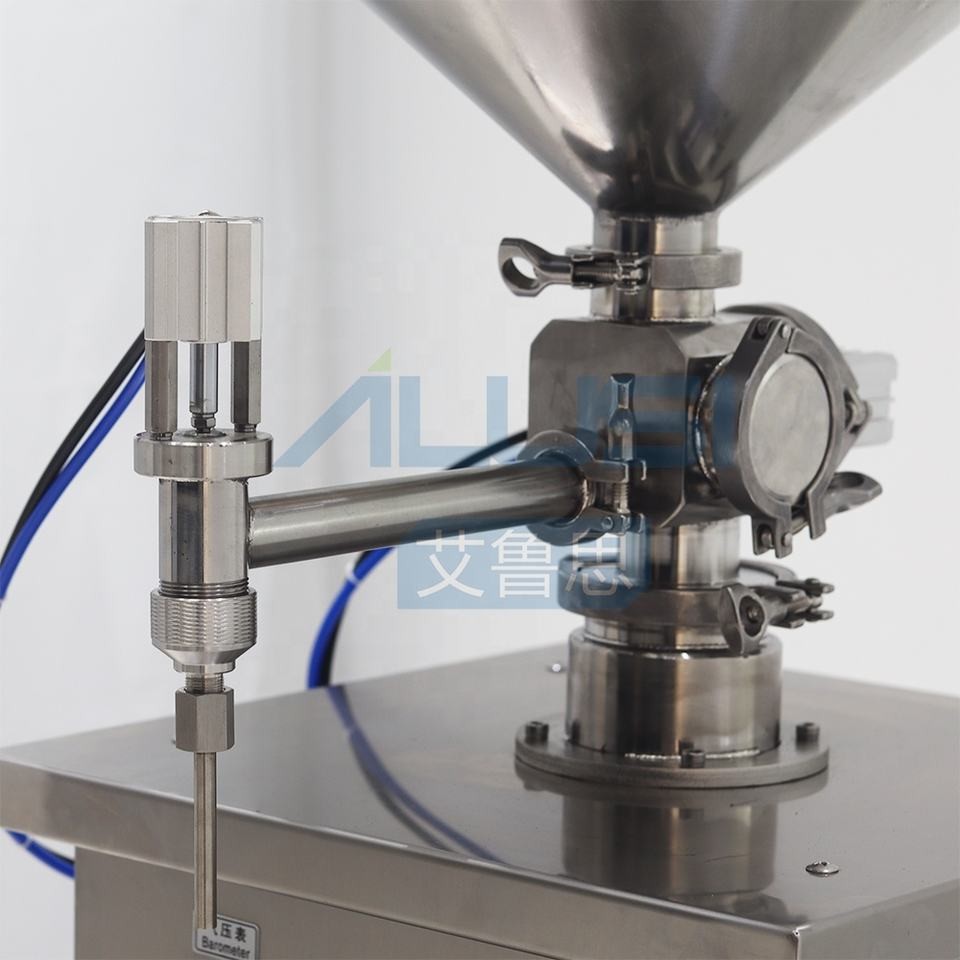

Driven Type : Pneumatic

Filling Accuracy : 99%

Filling Volume : 10-1000 Ml

Air Consumption : 0.05m3/Min

Air Pressure : 0.2-0.8MPa

Filling Speed : 5-50 Bot/Min(Adjustable)

Item NO.:AFM-ZC

Lead Time:10-15 Days

Product Orgin:China

Shipping Port:Guangzhou Port

Product Detail

Machine Hopper:

| SPECIFICATIONS FOR MASCARA FILLING MACHINE | |||

| Automatic Grade | Automatic continuous filling switch, or semi auto controled by foot panel(optional) | ||

| Driven Type | Pneumatic&Electrical | ||

| Air Pressure | 0.4-0.6MPa | ||

| Filling Range | 1-20ml/ 10-100ml/ 25-250ml/ 50-500ml/ 100-1000ml/ 250-2500ml/ 500-5000ml | ||

| Filling Speed | 20-30bottles/min(adjustable) | ||

| Filing Precision | ≤±1% | ||

| Voltage | 220V, 50Hz | ||

| Application:Mascara, lip gloss, liquid foundation and other liquid or paste materials, simple operation, easy to clean, and wide application range, have great practicality and benefit for a variety of types and diverse users. | |||

Factory:

Package & Delivery:

To ensure the quality of our service, we will follow the standard package upon delivery:

1. All products before delivery should be tested by assembly and commissioning engineers. Our salesman need to send the tested video to the customer to ensure working well of the machines. Precision parts need to be packed in film or carton.

2. All products are packed in wooden boxes. Firmly fix the edge of the foot of the equipment to adapt the machine to the requirements of loading and uploading.

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.

|

|

Cosmetic/Food Packing Machine Liquid Foundation Pressurized Filler Nail Polish Mascara Vertical Paste Filling Machine Images |